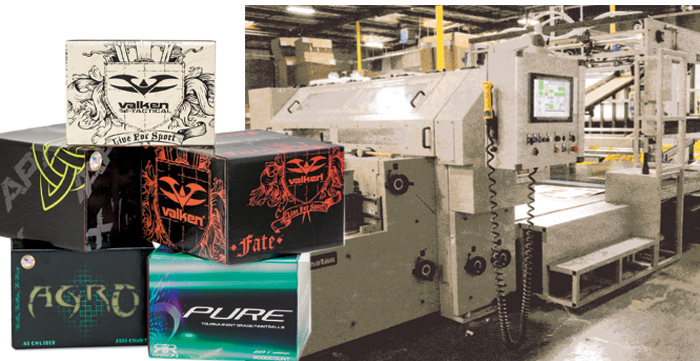

Litho-Laminating at TCC & WTC

Quality, quantity, and the skill of the operator are some of the common factors that are taken into con-sideration when deciding which is the right choice for a plant or job. Quality has been a point that many agree on. “Digital print, though very good, still doesn’t achieve the level of quality that labeling can. If you’re looking for a nice, shiny, photo quality finish, labels are the way to go,” says Nick Widera, Manager of WTC.

Quantities play a role in determining the break even point of digital printing vs labeling. “For lower quantities with multiple outputs, digital printing makes sense. Whereas, higher quantities and desire for higher quality graphics would lead you to labels instead, ” he says.

Your price is another factor that differentiates the two methods. Why? The up-front costs (about $5 to $6 million) of purchasing a high speed digital printer, parts, and ink are much higher than labelers. Plus, the labor costs are also greater due to the special skills required to be a digital printer. “We’ve had several integrated customers tell us that they are using labelers instead of evolving digital printers because of the trouble they have in finding operators with the needed expertise for quality results, ” says Chris Widera, CEO of WTC and TCC.

Litho-Laminating at TCC & WTC

- Quantity?

- Do you need a Full or Spot Label?

- What size?

- How many colors?

Are special colors required like Metallic gold or silver?

These require special consideration.

- Coating Options -

Is waterbase coating required?

Diamond Kote (UV Coating)

- Can you supply camera ready artwork, negative film with a proof

for color chromalens?

- Paperstock considerations -

Coated one side?

Grain – determined by laminator, usually longer scoring direction

SBS – 8, 10, or 12, will eliminate fluting

- Will this be a consistant run or a one (1) time run?