TCC Manufacturing Advantages

TCC Manufacturing Advantages

“We have the quality tools – with Just-In-Time Delivery – and we are using the latest technology to add value and drive down cost for our customers.” – David Limas, Quality Assurance and Plant Mgr.

Our Motto? On Time With Quality – No Excuses

Combined competitive advantages of our three entrepreneurial Arizona/West Texas converting companies:

- New multi-color flexo-folder-gluers with die cut sections and vacuum transfer. We will not crush flutes of RSC and FOL boxes. This results in a higher ECT rating, creating a stronger box.

- Our print registration is plus or minus one thirty-second of an inch.

- Laminator to laminate litho sheets to corrugated board at high speeds.

- We have the latest computerized gluing system on some of our new flexo-folder-gluers with high-speed cameras that inspect of each box for perfect quality control. (Quality Certification

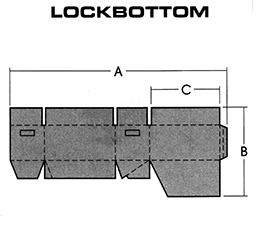

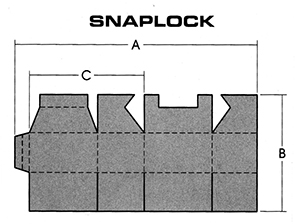

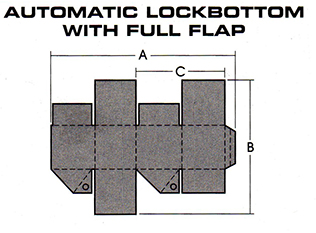

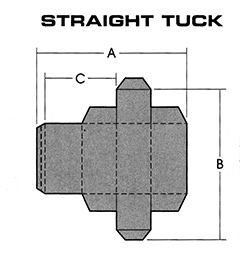

- Specialty gluers for trays, auto lock bottoms, snap locks – and more

- All of our machinery is fast set-up (10 minute average set-up). That can reduce warehouse inventory of finished boxes due to the ability to run and deliver on a true JIT basis.

- Each production machine has the back-up of another machine to insure JIT delivery.

- AIB Quality Certified (for food)

- ISO 9001-2018 for quality/safety certification.

- We sell all packaging suppliers direct and through brokers.

- We produce our own corrugated sheets on a NEW state-of-the-art corrugator in Phoenix.

- Jumbo flexo press for big boxes or two piece boxes.

- Large 3-color flexo-folder-gluers with inline die cutting.

- Flat die cutters using stripping jigs or vibrations.

- 2-color mini flexo for small boxes.

- We have 300,000 sq. ft. of warehousing in Arizona plus 3 warehouses in Mexico.

- A trucking fleet with our own drivers to control deliveries.of warehousing in Arizona plus 3 warehouses in Mexico.

to blueprint and specs.

As Entrepreneurs – we get it done !

As an entrepreneurial solution provider, we anticipate and react to changing niche market conditions.

For us, the key is to keep improving.

Develop new directions.

Adapt, for there is no permanent solution.

Specialty Glued Boxes

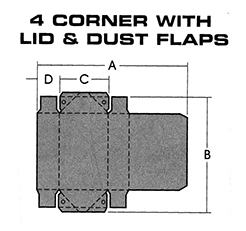

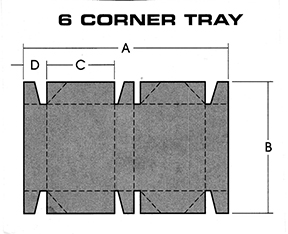

The die cut box styles run at high speeds on our specialty folder gluers will save customers time and money when packing our boxes, trays, or assembling displays. One style of box is a four corner tray, which is used in the beverage and garment industries. The four-corner tray is similar to a DST with the advantage of the sides being automatically glued at any of four facilities. No need for your end-user to glue or stitch them together.

Another style would be an auto bottom box, which is used in the electronics and food industries. This style is similar to an RSC with one exception. There is no need to tape the bottom of the box once it arrives at your customer’s facility. It is ready to pack once it leaves our plant.